-

-

-

Tổng tiền thanh toán:

-

VALQUA No. UF300

UNIVERSALHYPER™

This is a Sheet Gasket that can be used for the widest variety of fluids, and different applications are not required for acid or alkali fluids. It is effective for promoting gasket integration at a plant where both alkali and acid lines exist. This is a product that possesses high-temperature reliability equal to that of other High-performance Non-asbestos Sheet Gaskets (GF300, for example), thereby possessing both chemical resistance and high-temperature reliability.

Description

| Suitable fluids | Water, seawater, hot water, steam, air, acid (includes strong acid), alkali (includes strong alkali), salt aqueous solution, oils, alcohol, aliphatic solvent and its vapor, and various types of gas, etc. |

| Unsuitable fluids | Polymerizable monomer,toxic gas |

| Applications | Joint sections of cover flanges and nozzles and the like for pipe flanges, valve bonnets, towers & tanks, ovens, pressure vessels and heat exchangers used in various factories including power stations, oil refineries, steel plants and shipyards |

| Main Component | PTFE, silicon carbide |

| Color/Print | Gray / Blue |

Design Data

- Allowable ranges

Temperature and pressure classifications show individual service limits.Temperature (°C) Pressure (MPa) -200~300 3.5 - Dimensions

Thickness (mm) Size (mm) 1.0 1270×1270 1.5, 2.0,3.0 1500×1500 - Design Criteria

The values for Compressed Non-asbestos Fiber Sheets defined in Appendix G to JIS B 8265 can be applied to m and y values of High Performance Non-asbestos Sheets.Thickness

(mm)Gasket factor

“m”Minimum design seating stress

“y”(N/mm2)3.0 2.00 11.0 1.5 2.75 25.5 1.0 3.50 44.8 - Recommended Tightening stress(MPa)

The recommended tightening stress is the pressure required under standard conditions without consideration to the endforce due to internal

fluid. It is the stress on the contact area of the gasket

| Fluid | Recommended tightening stress (MPa) |

| Liquid | 25.5 |

| Gas | 35.0 |

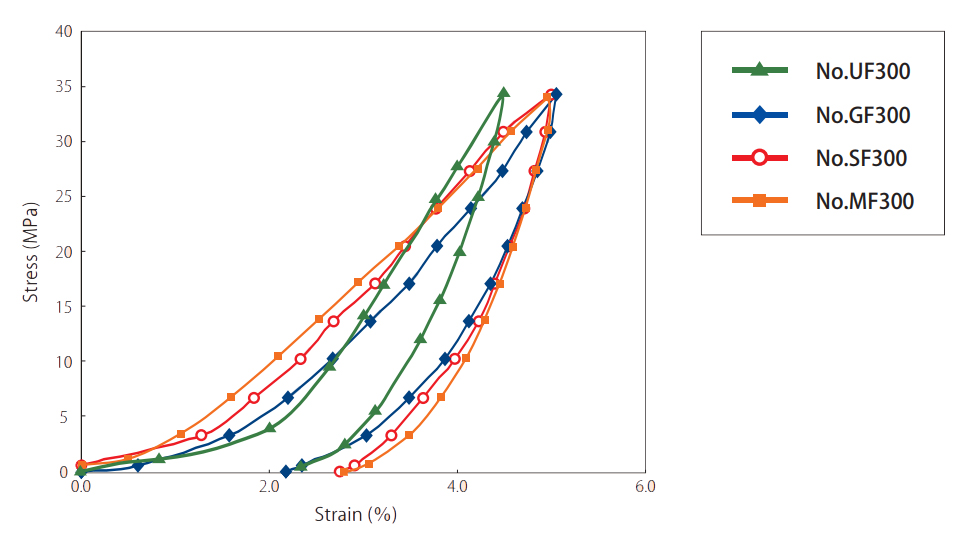

Stress strain characteristics of High Performance Non-Asbestos Sheet

(Dimension of test piece:JIS 10K 25A t =1.5mm)